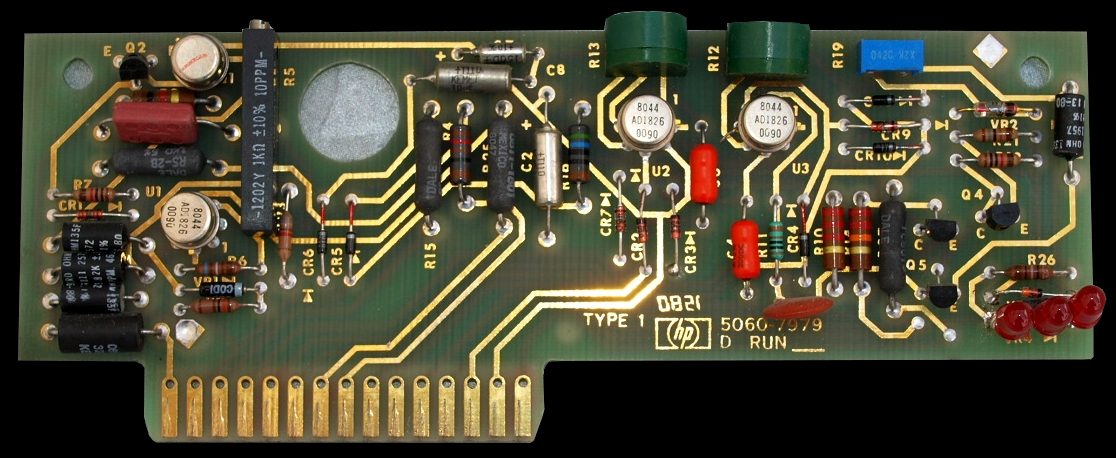

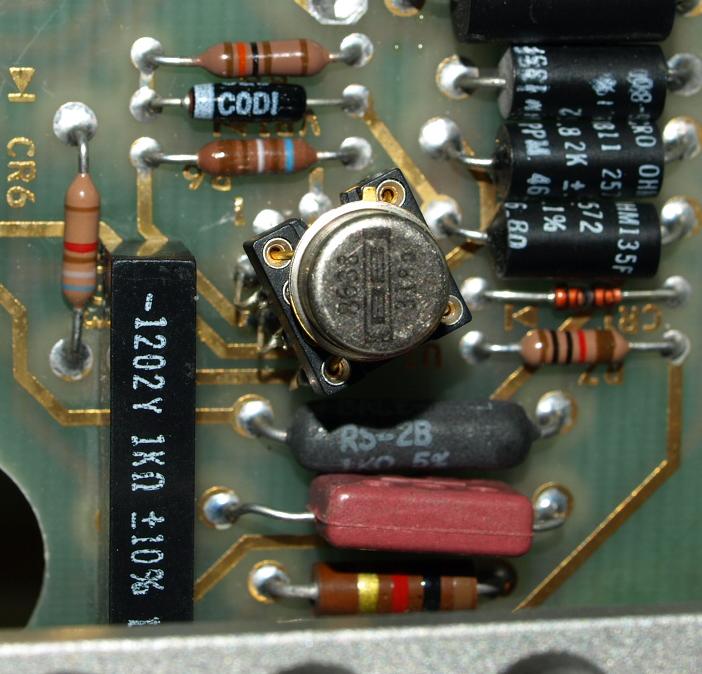

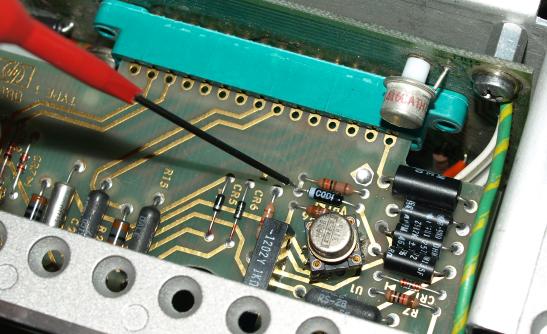

Changing operational amplifiers can

be a terrible task getting the control loop stable again. First I tried

some DIL-8 types, later I choosed some good performance TO-5 types.

Their pinout and offset trimming pinout was similar to the old 741

family. All three control loops are stable over load, time and

temperature, these are three things you must observe. The used Difet

has much lower input bias currents and noise, higher open loop gain and

less offset voltage and drift and the speed is higher, but be careful

with high speed types some tend to oscillate. - choosed type is well

suitable for integrator functions. I won't recommend the type, try

yourself there are many available types on the market. But don't make a

hype by changing op amps, the circuit worked also nicely with the

old 741 family.

Calibration Procedure

This chapter shows how to calibrate the instrument.

For a accurate calibration please read the manufactorer manual.

The description here follows close to the instruction manual - but not in all items.

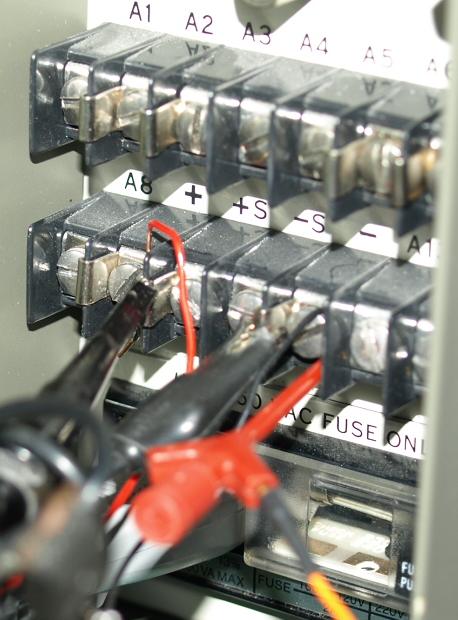

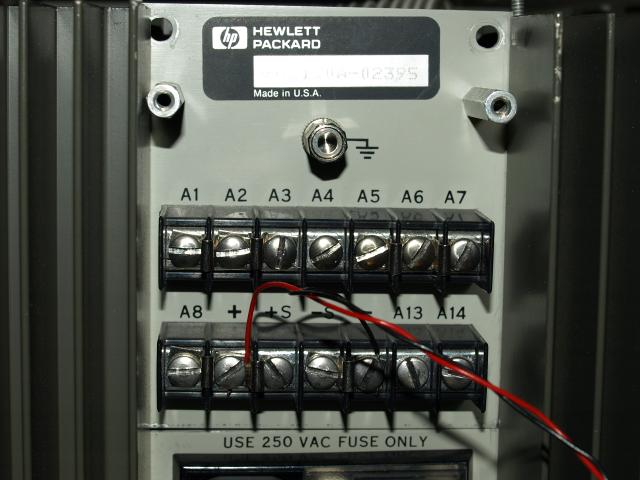

Always observe all jumpers on the

photos - I can't a warranty that I not forget onetimes to mention when

jumoers shall be removed or replaced again.

The photos are correct, the text max be not. I repeat it again, use the original manual for a valid calibration.

1. Mechanical Meter Zero

Turn OFF instrument, insert a sharp pointed object in the black slider

and move pointer position clockwise until the pointer will reach zero

point.

Move pointer slightly counterclockwise to free the pointer from suspension.

2. Gross Current Limit Adjustment

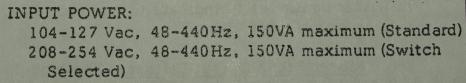

Use a

33 ohma load at

40VDC output under lowest AC-line voltage

An AC variac is a recommended source for repair and calibration.

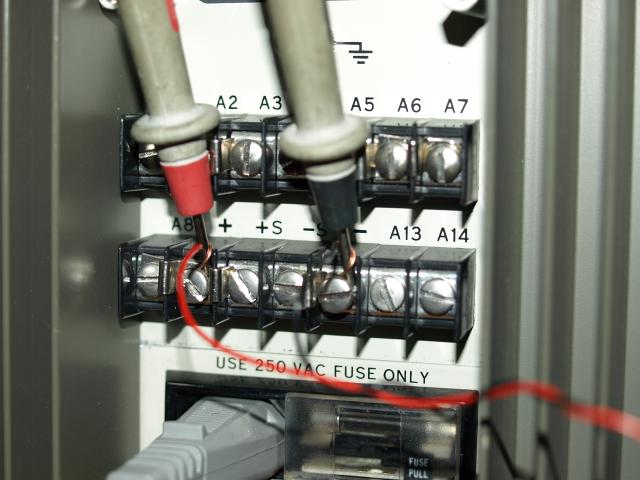

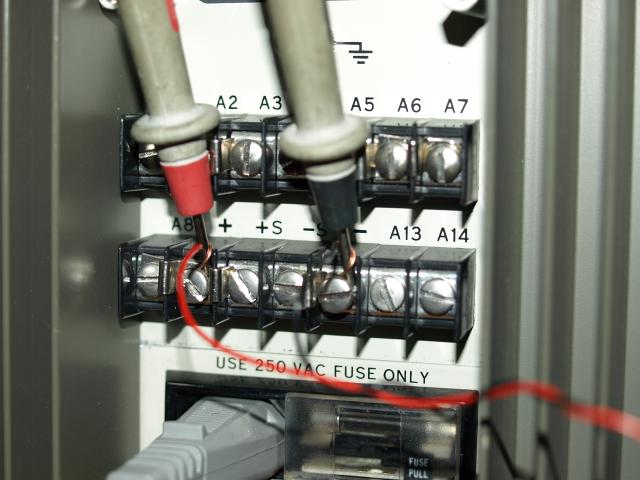

34 ohm load resistor

Connect load on the rear output. The rear output is sensed., the front output not.

Instrument has many programming possibilties in current and voltage

through external analog settings, difficult to describe in detail, read

manual.

Keep the load cool - 47 watts applied power.

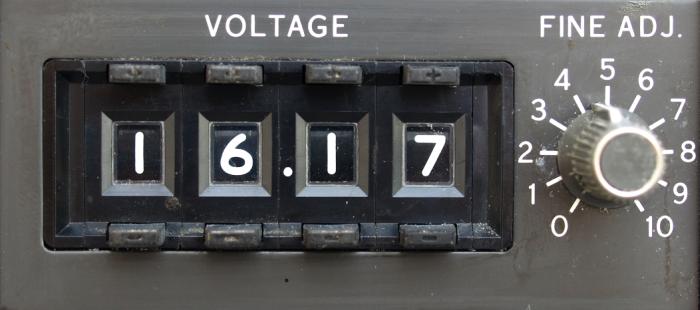

Set output voltage to

40V

Adjust cross current limit on the trimmer in the middle

Set Front Panel Meter to

AMPS position.

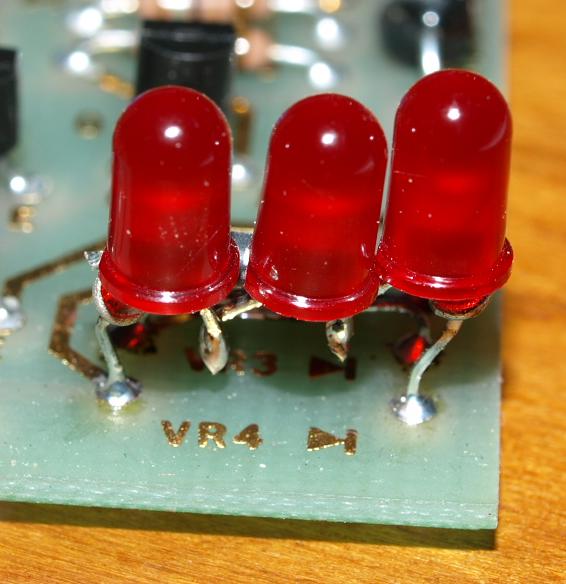

Turn CURRENT control full clockwise, adjust trimmer so that current mode LED just starts lights at

60% of maximum rated current.

I removed the load after adjustment.

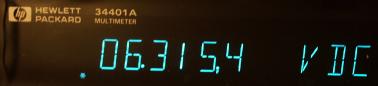

3. Reference Supply

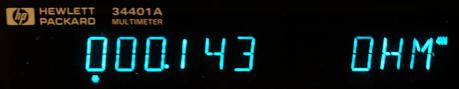

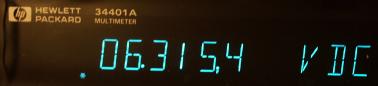

Warm-up a DMM with a high accuracy. Warm-up the power supply for at least 30 minutes.

Measure voltage on the temperature compensated zener voltage reference against + output.

The meter should read a voltage greater than

6V. If not read the instruction in the manual what to do.

With 6.3V here the zener current is large enough that the 1N829 will operate with a recommended operating current range.

If the diode operates under too low currents, important parameter worsen:

- temperature coefficient

- dynamic resistance

- noise

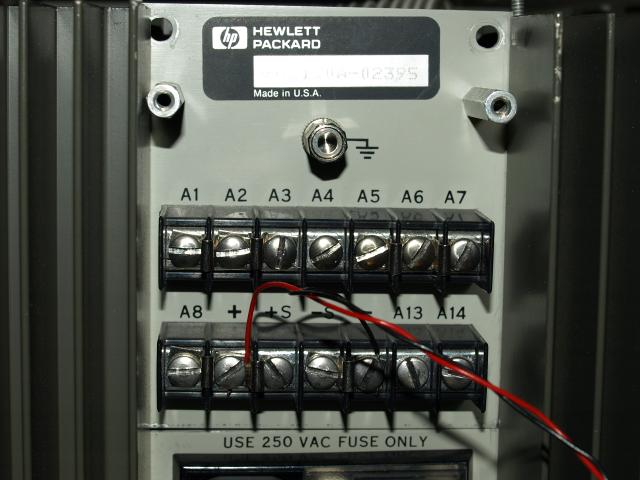

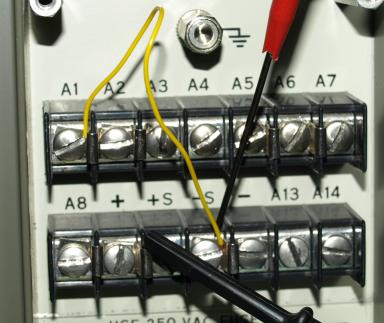

4. Zero Output Voltage

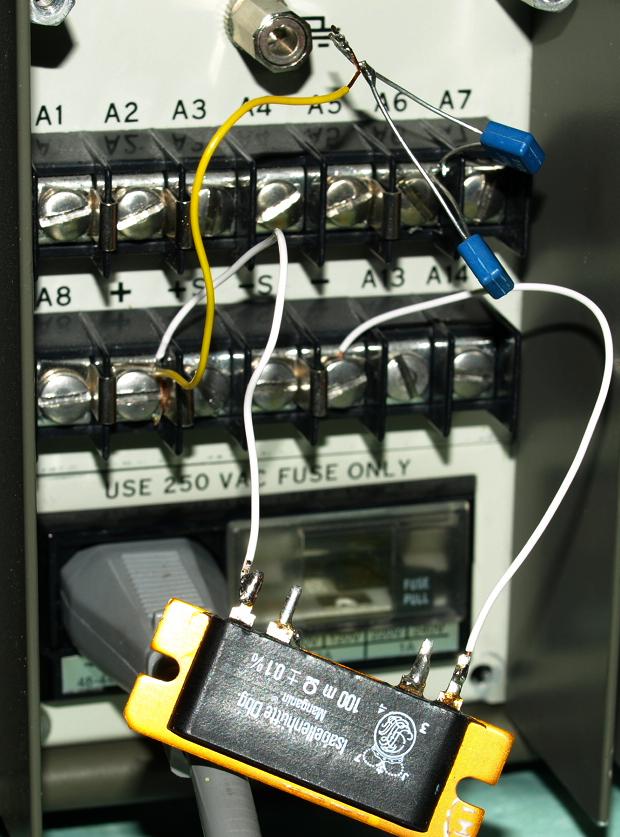

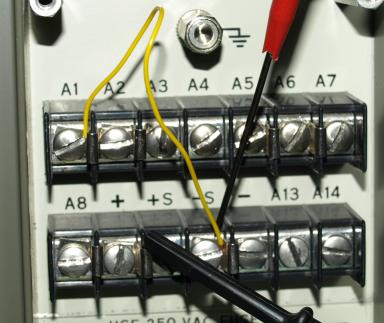

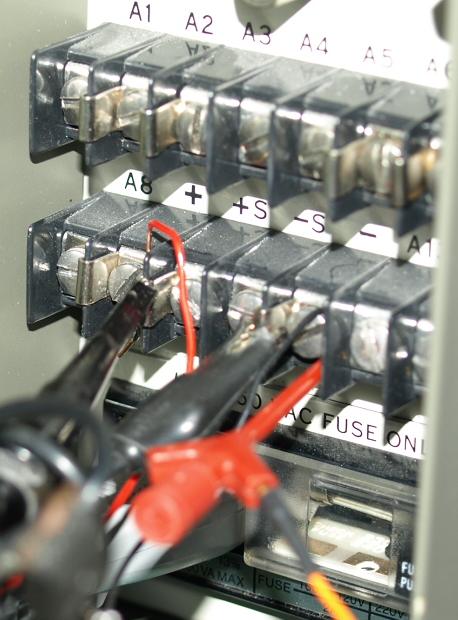

Short out the voltage control loop by a short-circuit (yellow wire)

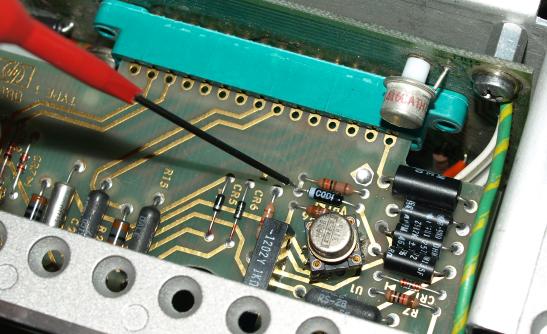

Adjust trimmer (green) R13 on board A2 for a

-450+/-50µV between +S and -S.

(Note: I adjusted the voltage to exactly zero voltage not to the recommended value in the manual).

This trimmer sets the opamp offset voltage of the voltage control loop to zero (with my adjustment).

Zero voltage values differing, depending if measured on rear or front terminals - I choosed the rear terminals.

I hope your are satisfied.

Observe for some minutes for a stable voltage, low frequency oscillations and offset drift can be detected.

In this measurement the yellow wire applies a zero voltage to the noninverting input of the voltage loop operational amplifier.

The +output applies on the inverting op input, when both voltages are

equal the loop is in regulation. The trimmer sets the operational

amplifer offset voltage to zero.

5. Voltage Programming Current

Turn power supply OFF.

Connect the yellow wire as shown.

Remove jumper between A2 and A3

One side of the yellow wire is connected to a high precision 1 kohm series resistor conncted to -S.

(here a two paralleled 2k used).

Apply the high input impedance DMM across the resistor.

Turn ON supply.

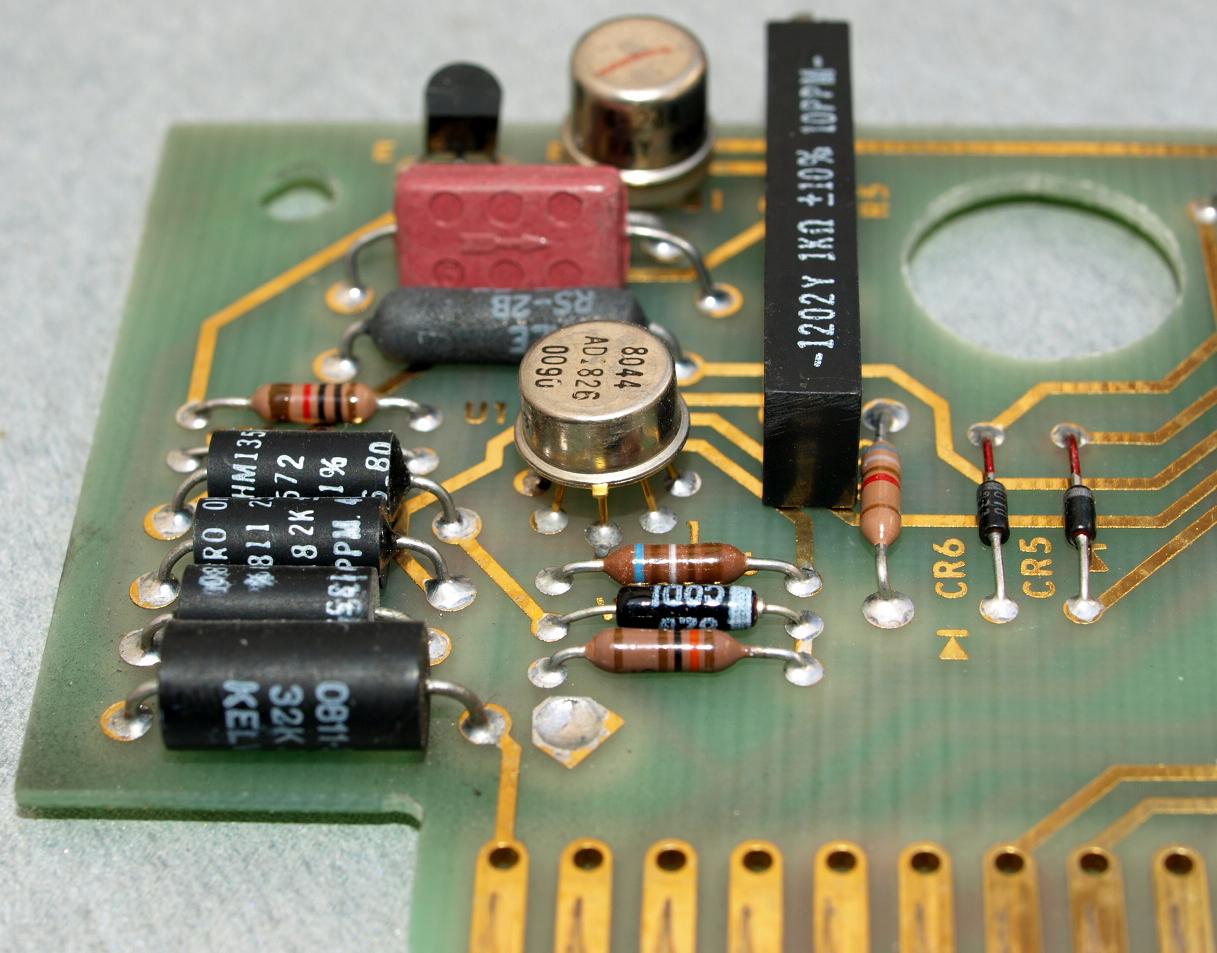

Adjust A2 R5 (long black trimmer near 1N829) for a reading of

0.5V +/-5µV

Turn OFF supply

Replace A2 to A3 jumper.

I hope your are satisfied.

This adjustment set the current flowing through the digital output voltage setting resistors.

If this voltage is not stable, then there are problems in the +16V

reference voltage loop. Observe this value for stability, all

output voltages depending on this voltage.

This measurement sets the scale factor of the output voltage control

loop. This constant voltage drives a constant current through the

digital selectable gain setting resistors.

Resulting voltage across gain setting resistors program the voltage control loop.

6. Voltmeter Calibration

Adjust A1 R22 (right trimmer near the front panel in the right corner) for a corret front panel voltmeter reading.

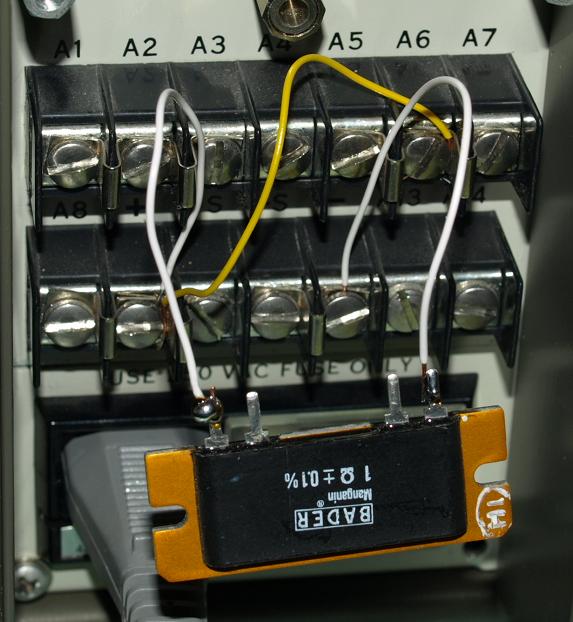

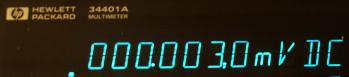

7. Zero Output Current

Turn supply ON.

Program output for 2 volts.

Place the yellow wire.

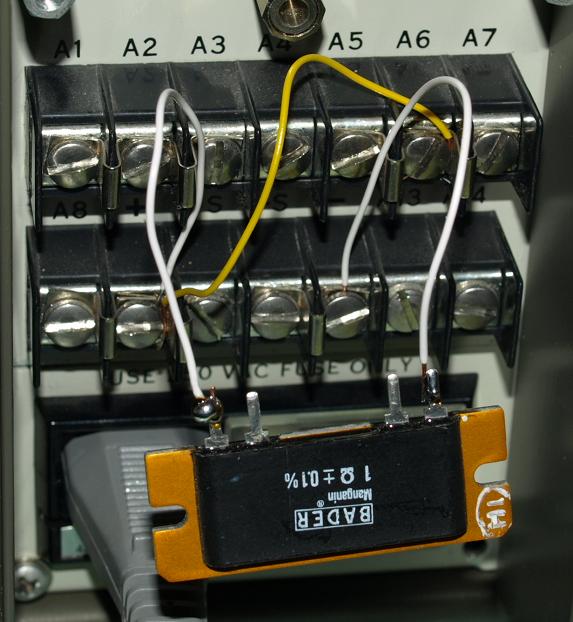

Connect a 1 ohm resistor and measure voltage across resistor.

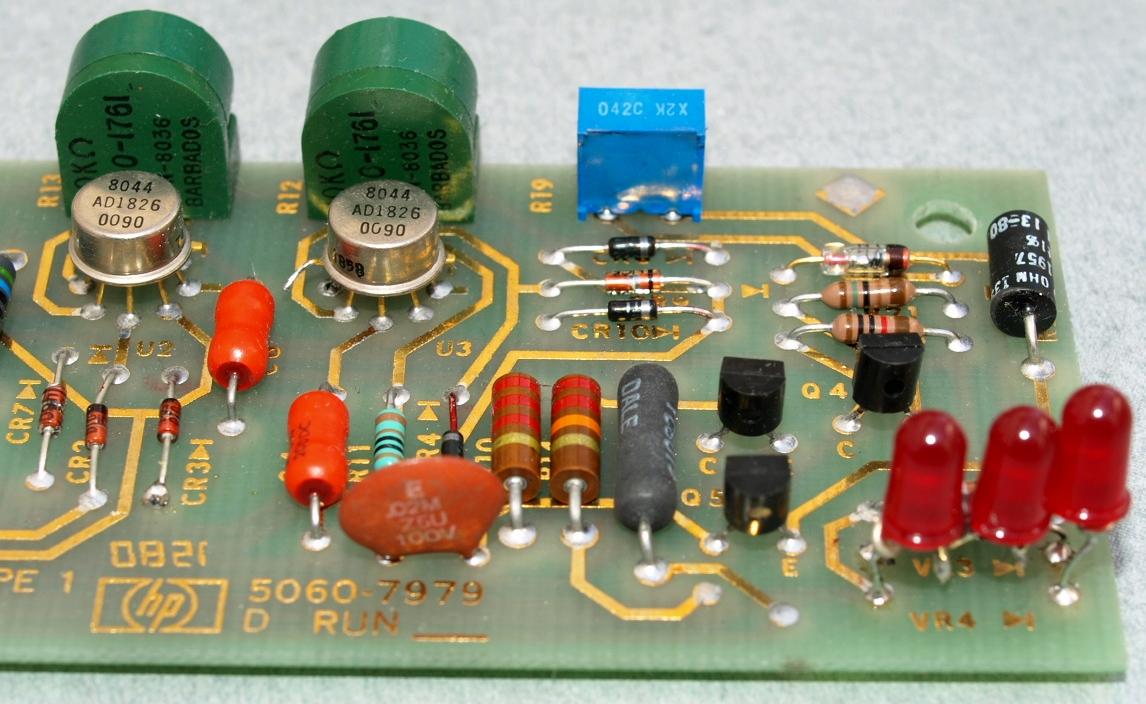

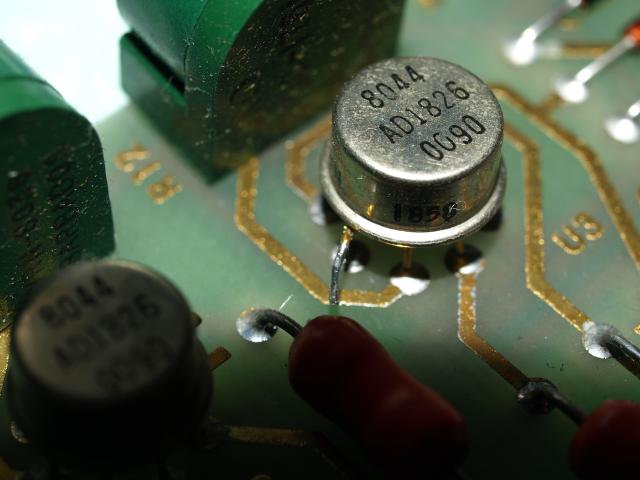

Adjust A2 R12 (green trimmer) to

0V+/-10µV on DMM

Turn supply OFF.

Remove yellow wire.

Don't use that long lead wires like shown, causing error.

Current control loop set to a zero output current. Trimmer R12 (U3 opamp offset contro)l sets the current in the load to zero.

I hope your are satisfied.

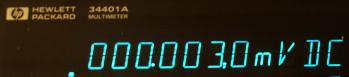

Zero Current = 0.003mV/1ohm = 3µA

Observe this value for stability within some minutes.

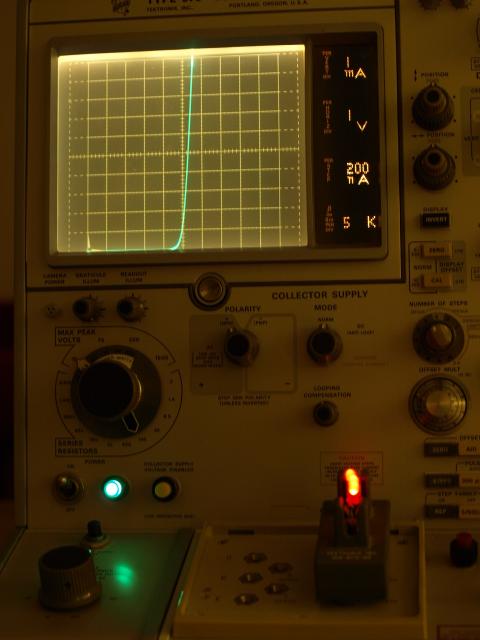

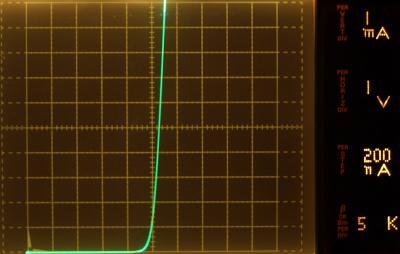

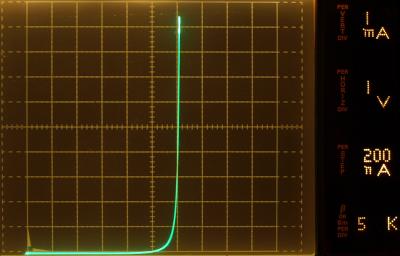

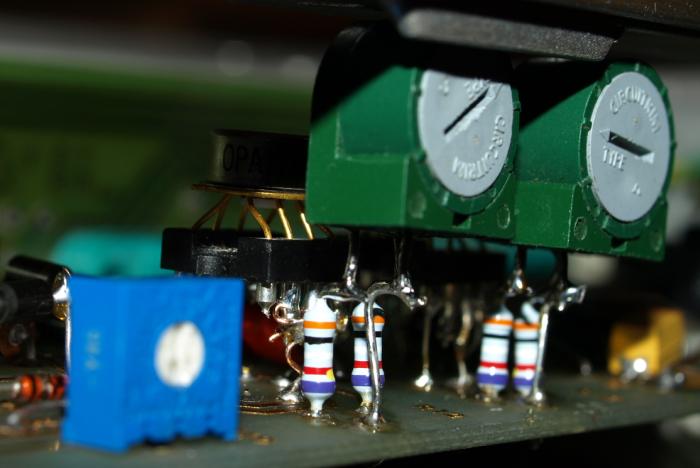

8. Current Programming Current

This adjustment will set the programming constant current flowing through the CURRENT MODE potentiometer.

A diode-transistor current mirror generates a 1mA current.

The CURRENT MODE potentiomer has a nominal 1k resistance, with a

1mA current 1 volt drops - and this voltage set the current loop on the

noninverting opamp input.

The internal output current sensing resistor has 500mOhm and applies on the inverting opamp input.

With 2A output current:

2A*500ohm=1 volt

1mA*1kohm=1 volt

When both voltages are equal the current control loop is in regulation.

This adjustment ensures that a maximum set clockwise CURRENT MODE 1k

potentiomer will set exactly the output current limit to 2A.

For example when using a 1k 10-turn potentiometer the current limit could be easily calibrated to 200mA/360°.

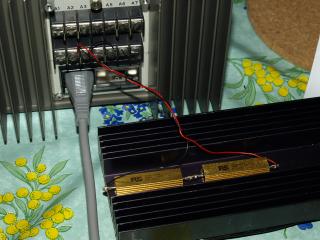

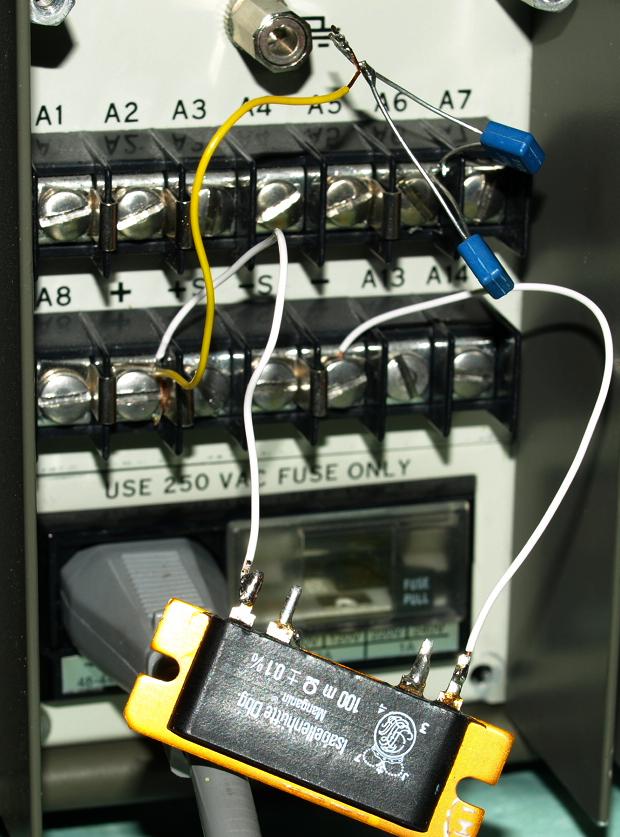

Such a calibration don't work - 100 mOhm resistor with long thin wires.

Turn OFF supply

Remove jumper between A6 and A7.

Connect 100 mOhm across output.

Connect a precision 1k resistor A6 and + output

DMM on output voltage

Program for 2 volts and turn ON

Adjust A2 R19 (blue trimmer) for a reading

-0.2V+/-250µV

Resistor in 4W measurement at the end of the white wires , a bad

configuration, the -0.2V can not be reached. This method works only

with precise 0.1 ohm between + output and -output.

I choosed another method:

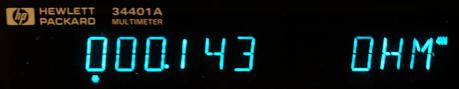

Measure the voltage drop across the 1k precision resistor, if A2 R19

exactly adjusts a 1V drop, the current limit will reach 2A with a 1k

potentiometer in maximum clockwise position.

This was a good example:

If you calibrate something - always think about what you are doing - try to understand the circuit first.

9. Ammeter Calibration

Adjust A1 R17 (trimmer closest to front panel meter) for a correct reading, compare and measure the load current with a DMM.

Accuracy Measurements

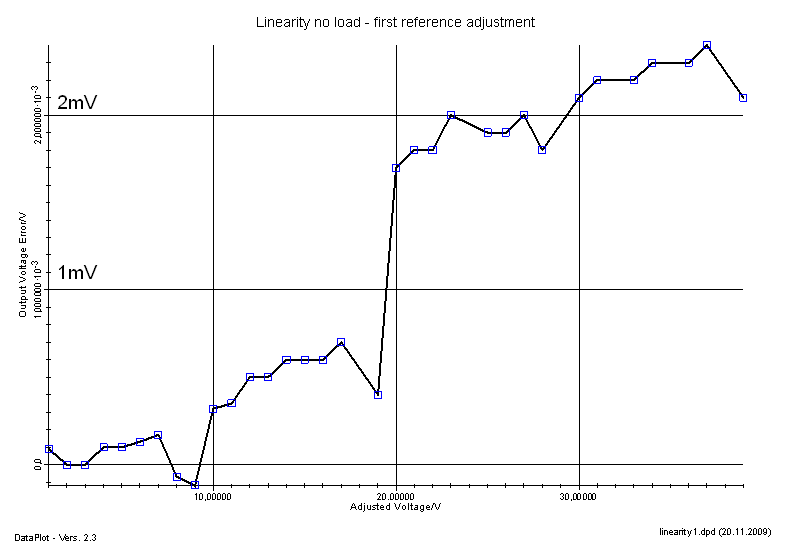

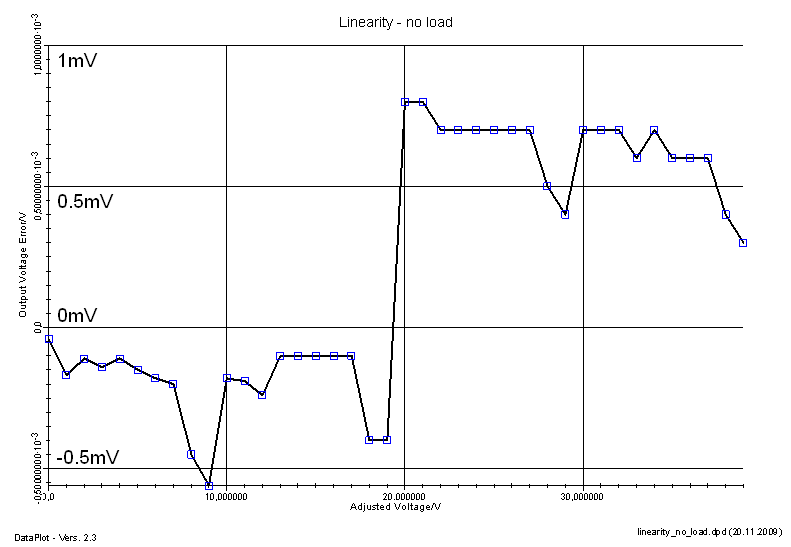

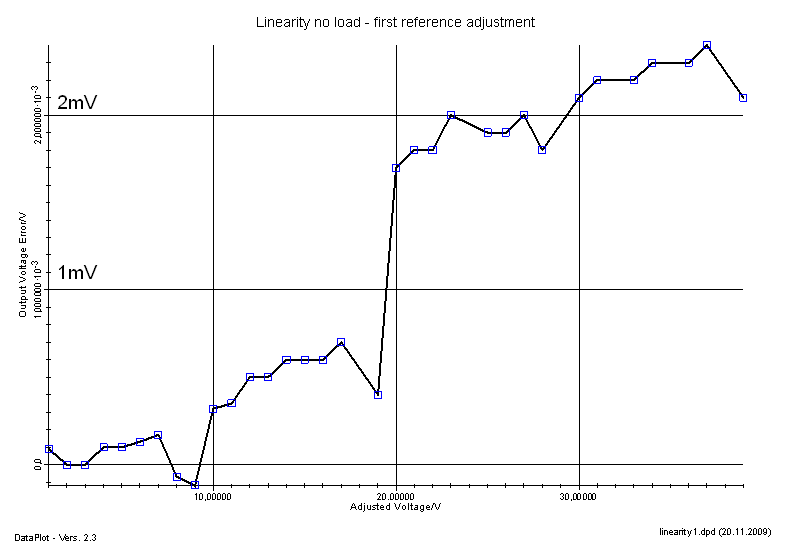

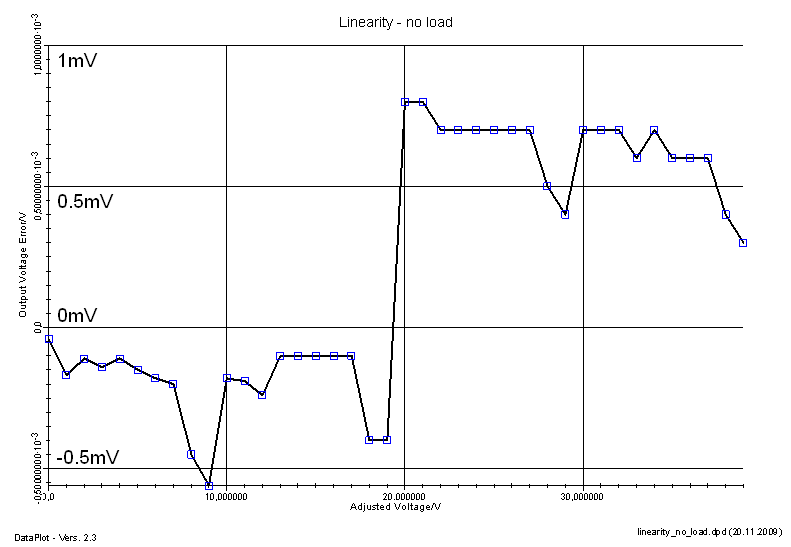

Linearity without load

Power Supply and DMM (34401A) warm-up for 1 hour.

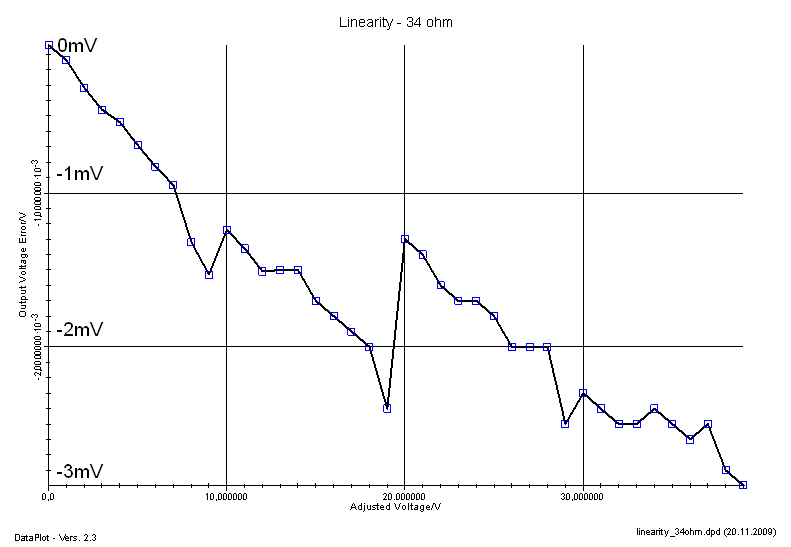

This plot shows the Output Voltage Error vs. Adjusted Voltage

This plot shows the Output Voltage Error vs. Adjusted Voltage with a

slightly readjusted internal reference voltage trimmer R5 on board A2

The maximum error reaches:

+800µV for a 20 volts output.

-600µV for a 9 volts output.

This is an accuracy within:

+0.004% (+40ppm)

and

-0.006% (-60ppm)

This power supply reaches almost absolute 16 bit accuracy.

1LSB=40V/65536=610µV

After repeating it would be a good idea trying to fine trim the digital resistor devider with parallel or series resistors.

A trimming could remove the large jump between 19V and 20V and an absolute 16 bit performance could be reached.

This was a time demanding measurement applying 1 volt steps and writing down the results.

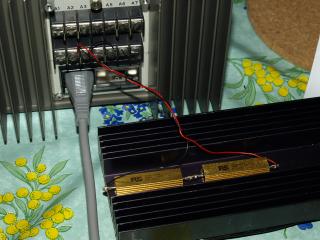

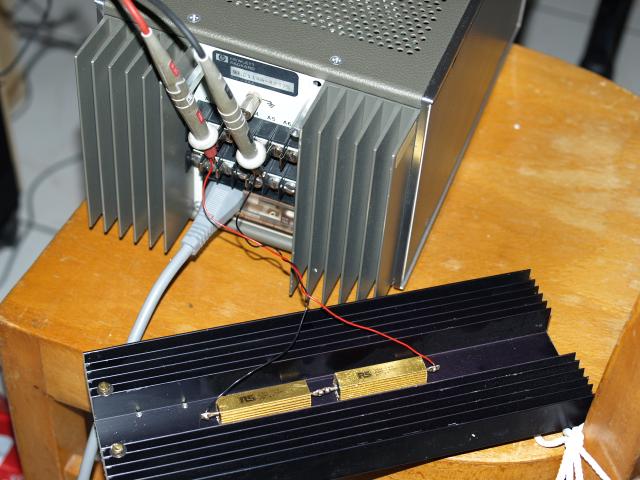

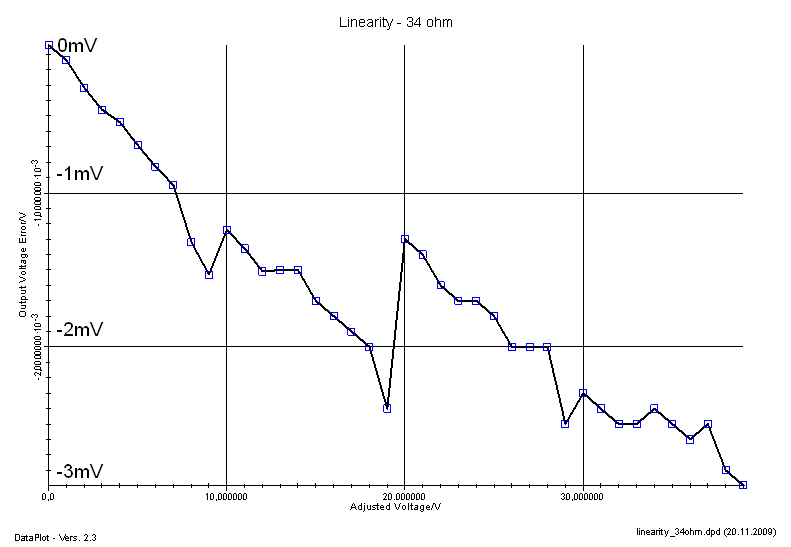

Linearity with a 34 ohm load

The load will cause maximum 1.2A and 48 watts power

.

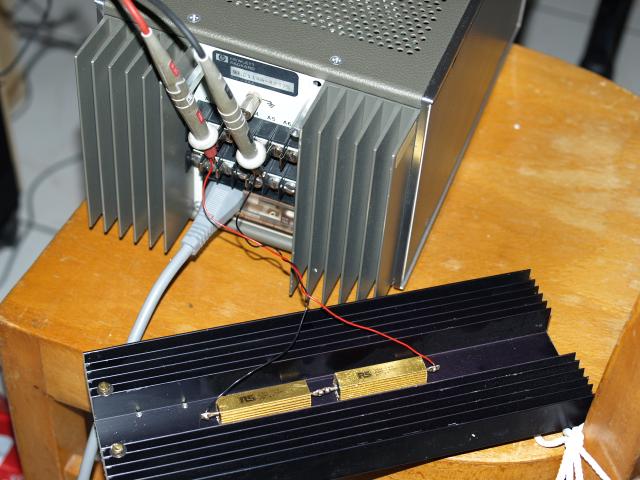

34 ohm load on a heatsink

This is not a good sense and load connection, the wires are under the srcews.

Power Supply and DMM (34401A) warm-up for 2 hours.

The voltage drop in the terminals with rising current.

Manufactorer specifies a 50µOhm output resistance, under a 1.2A

current cause this a voltage drop of only 60µV. The bad

connection is the reason for the large error.

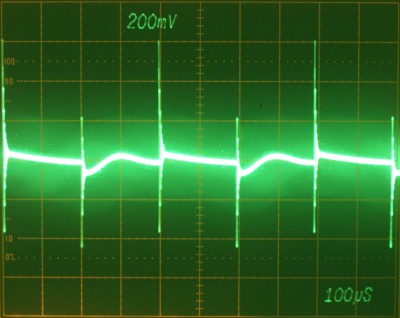

Dynamic Measurements

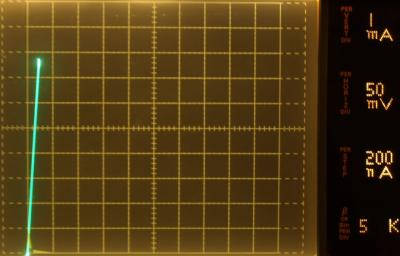

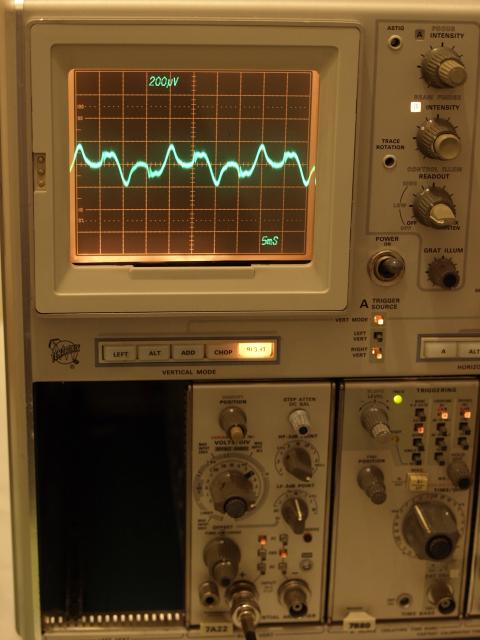

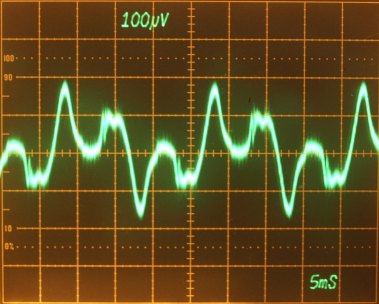

Output noise with and without load

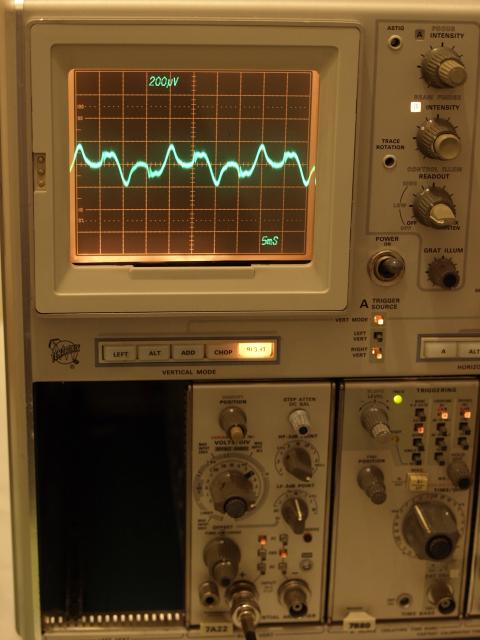

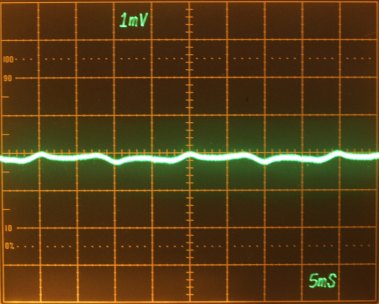

Using a

7A22 set to a 10Hz - 1MHz bandpass

Oscilloscope powered with the AC variac, 6114A on AC-line

Using shielded cables. These kind of maesurement are difficult, you

never know if measure real signals or parasitic ground loop signals.

Try different grounding schemes, I haven't tried other ground and shielding configrations here.

No load

(Oscillogram looks similar to any output voltage).

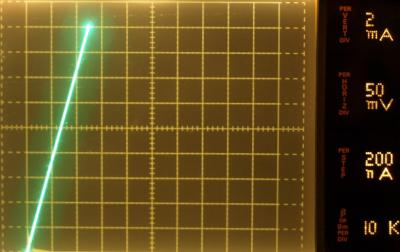

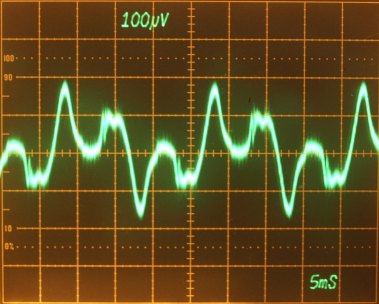

34 ohms load at 10 volts

(Unexpected, ripple had become lower with load).

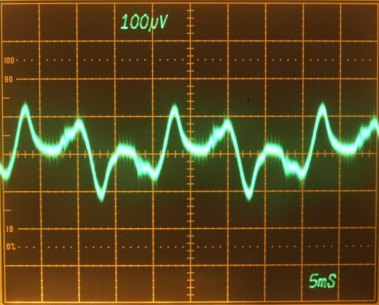

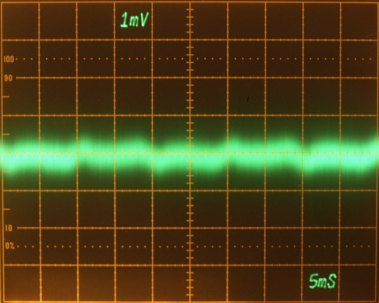

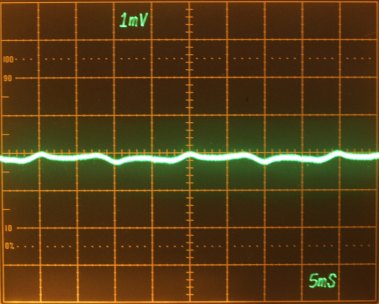

Changing to a

7A13 Amplifier Plug-In,.

Under use the internal adjustable DC voltage on the inverting input.

34 ohms load at 10 volts.

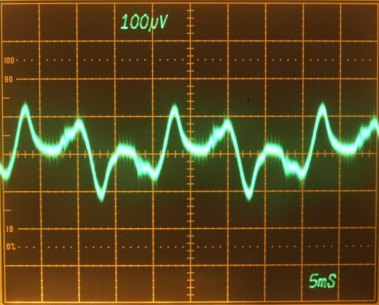

7A13 set to bandwidth DC to appr. 100 MHz (full range)

34 ohms load at 10 volts.

7A13 set to bandwidth DC to 5 MHz.

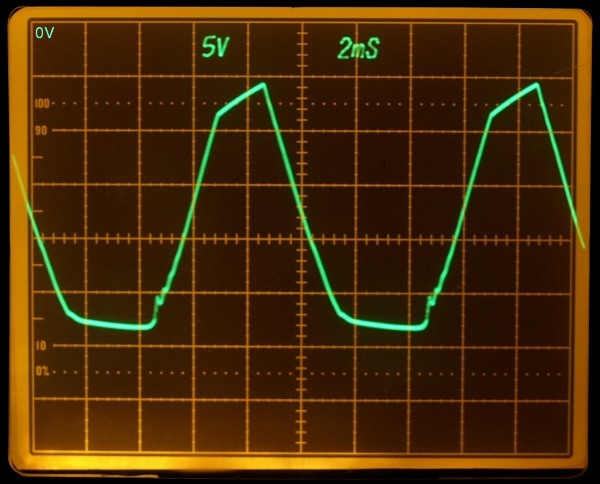

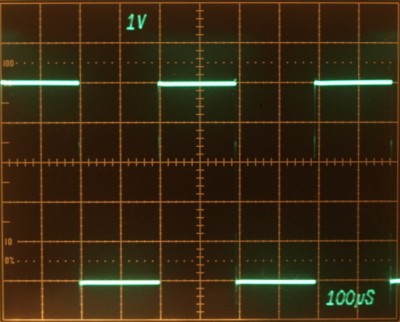

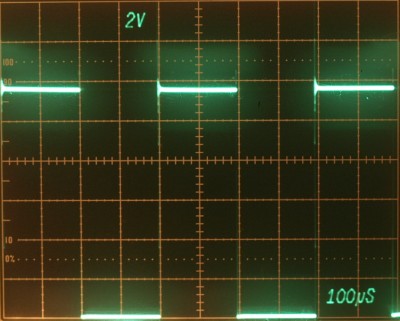

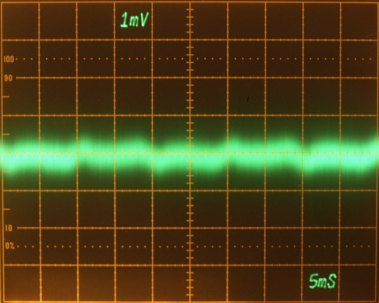

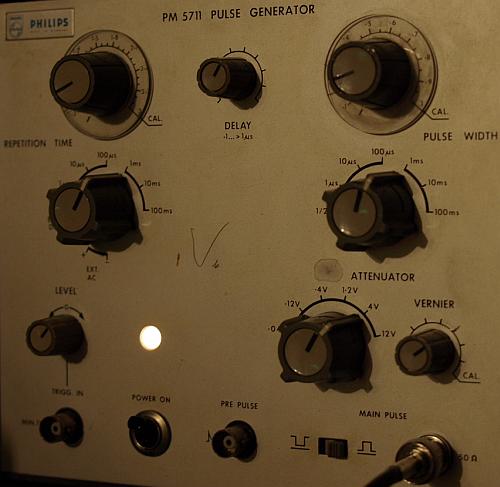

Output with a switched load

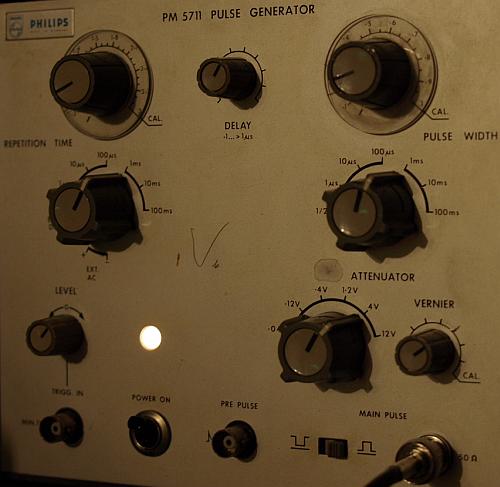

34 ohms load switched by a small MOSFET controled by a pulse generator.

Output voltage probe measured directly on the sensed outputs.

output set for 12 volts

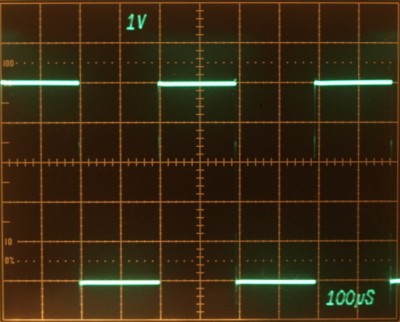

Using a 7A13 in AC position up to full bandwith and a second intensified timebase.

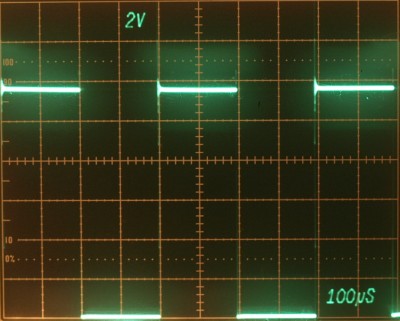

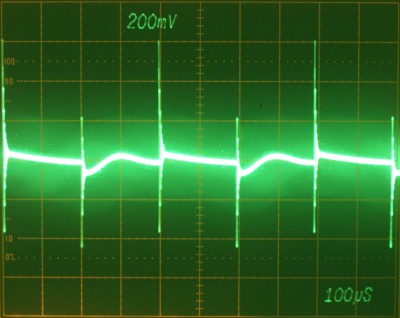

Upper Trace AC coupled power supply output, 100µs/Div.

Lower Trace zoom of intensified zone, 2µs/Div.

The inductance of the load wire-wounded load resistance, the wires

togehter with capacitances from the MOSFET and the output creat a

LC tank oscillating at approximately 800kHz resonance frequency.

The power supply contol can't reject this higher frequency contents,

this is an excepted result due to the integrating precision

control loop character.

Set the puls generator

Gate Source Voltage

Drain Source Voltage

With this parasitic-LC load (34 ohms) appearing very high switching transients of more than 5 volts.

Power Supply Output voltage

Control loop rejects this higher frequency contents from 5 volts to approximately 600mV.

Conclusion

I like this fine power supply, handy size, current control,

overvoltage protection, high accuracy and less ripple make it a useful

instrument for the labor.

It was much work to repair all the faults.

When I remember repairing this instrument costs me about 30 hours of

hard working, including the time for understanding circuit and

calibration, not counting the hours of writing this note.