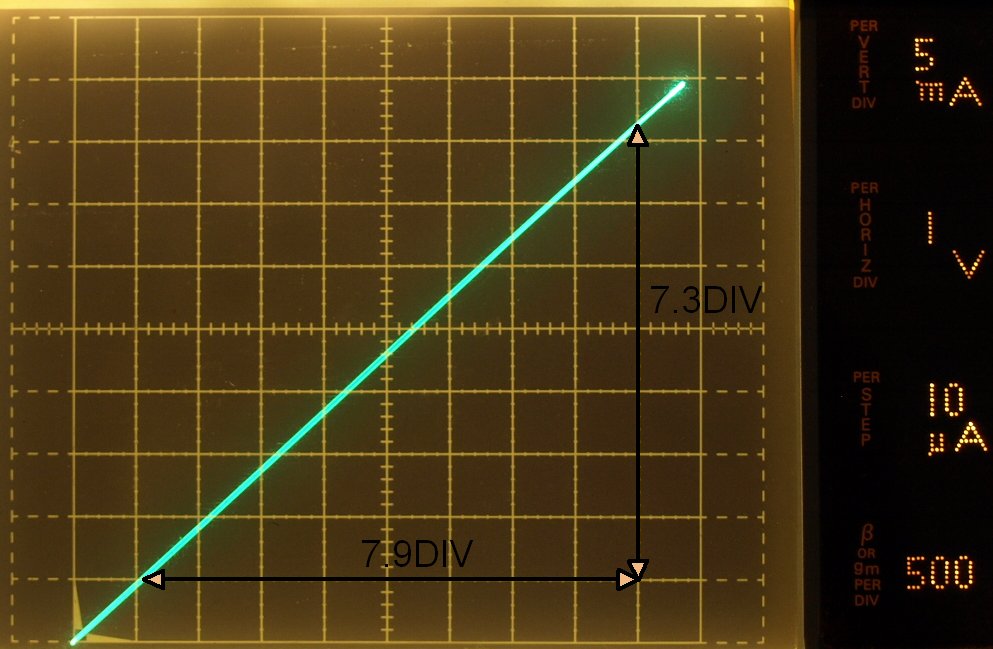

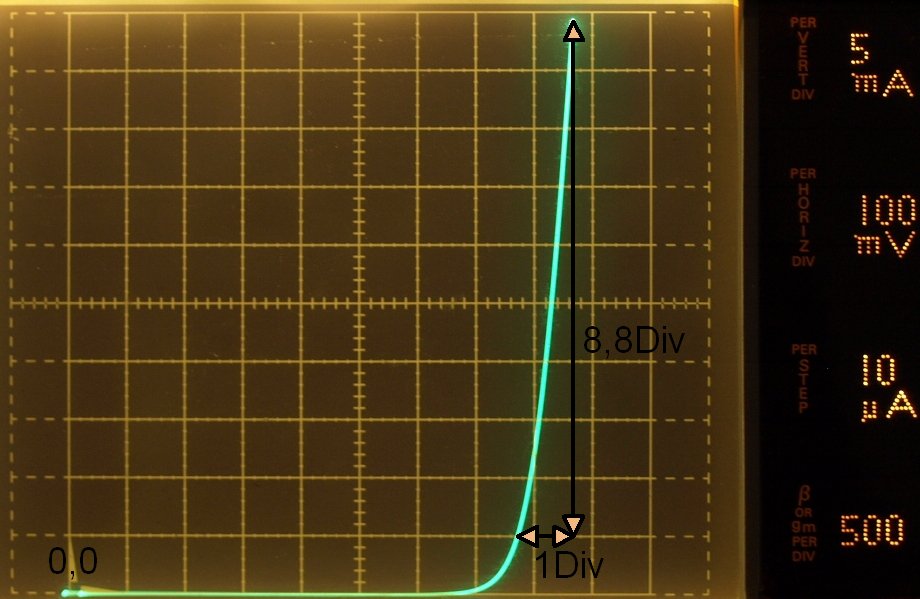

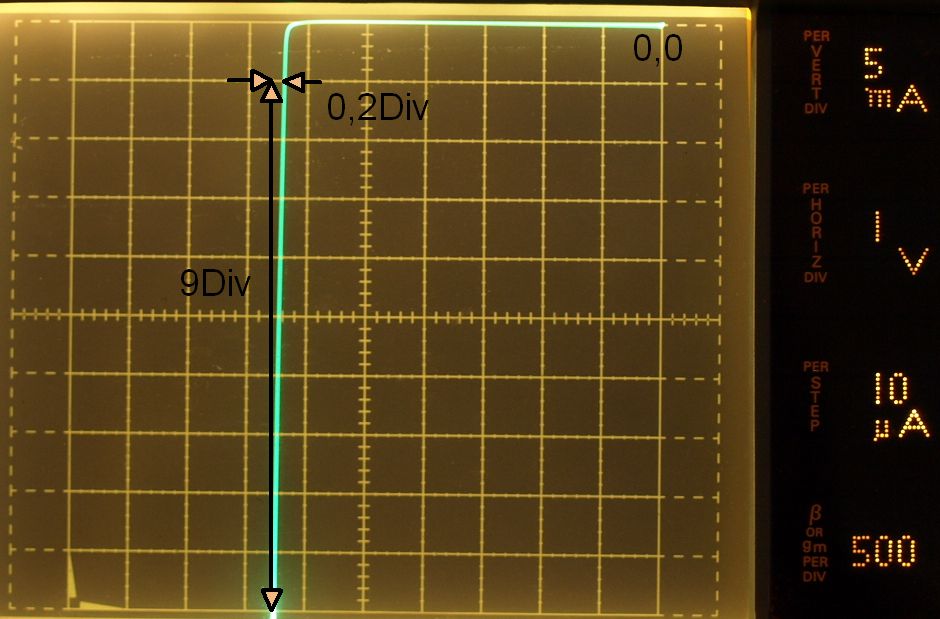

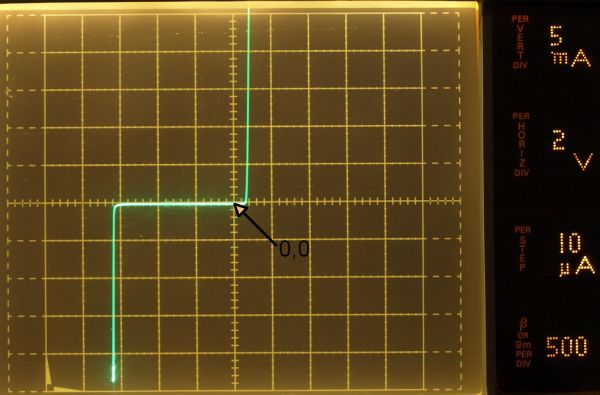

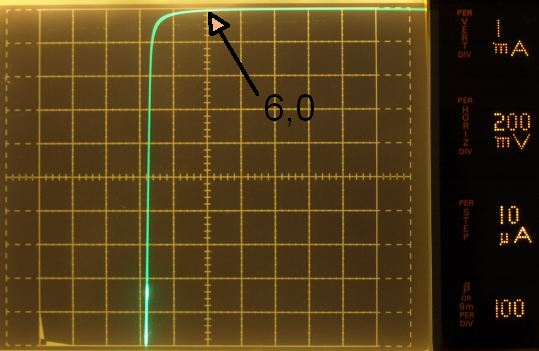

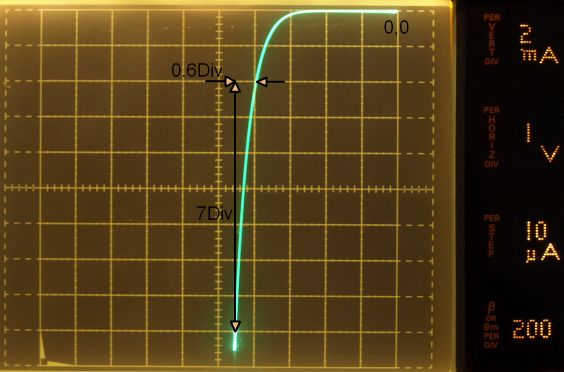

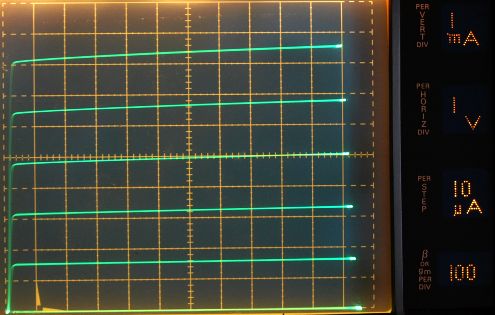

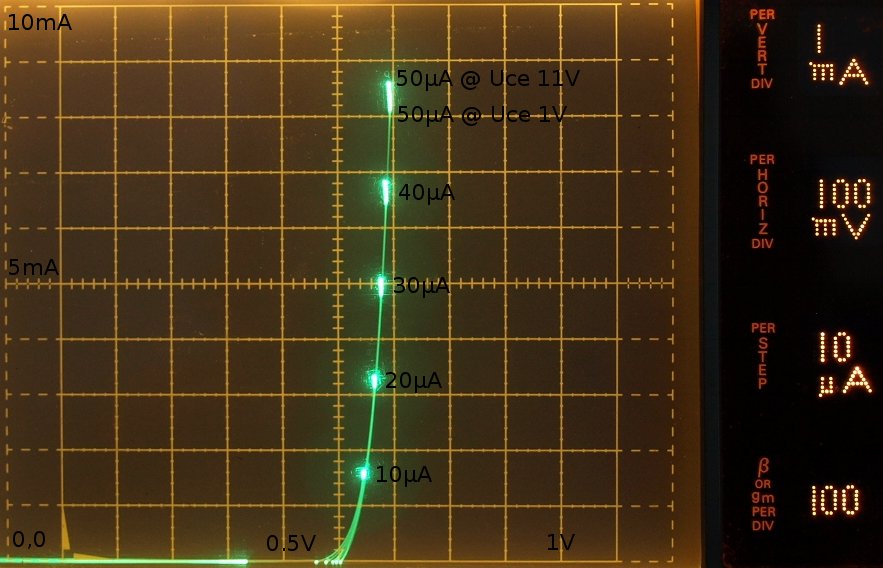

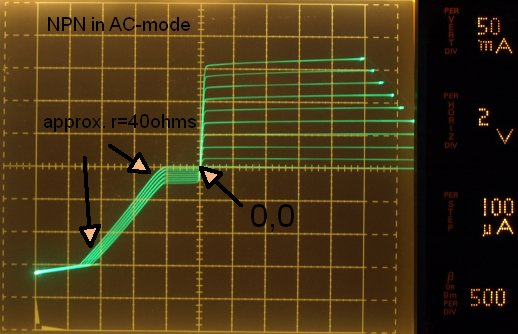

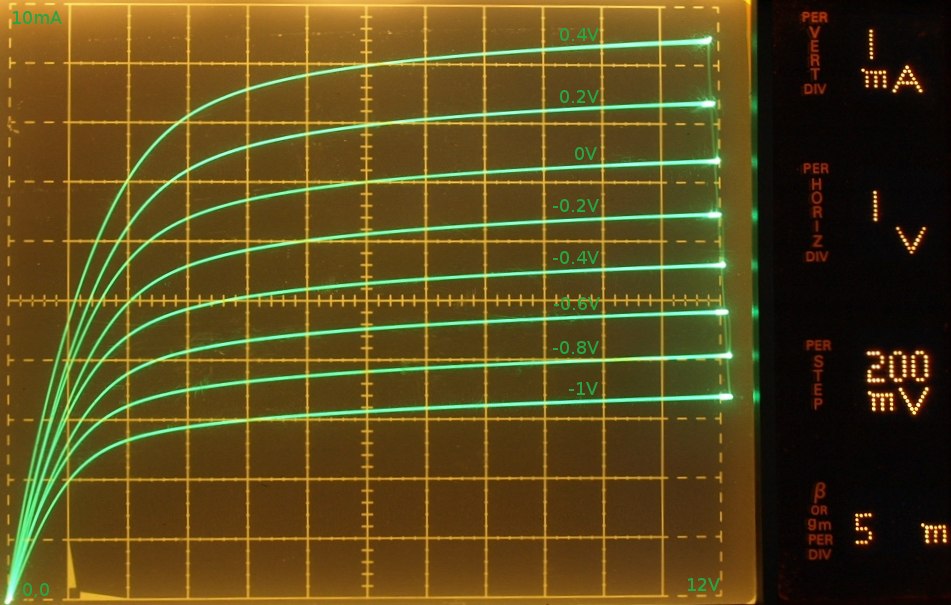

Vertical Deflection Factor = 5mA/Division

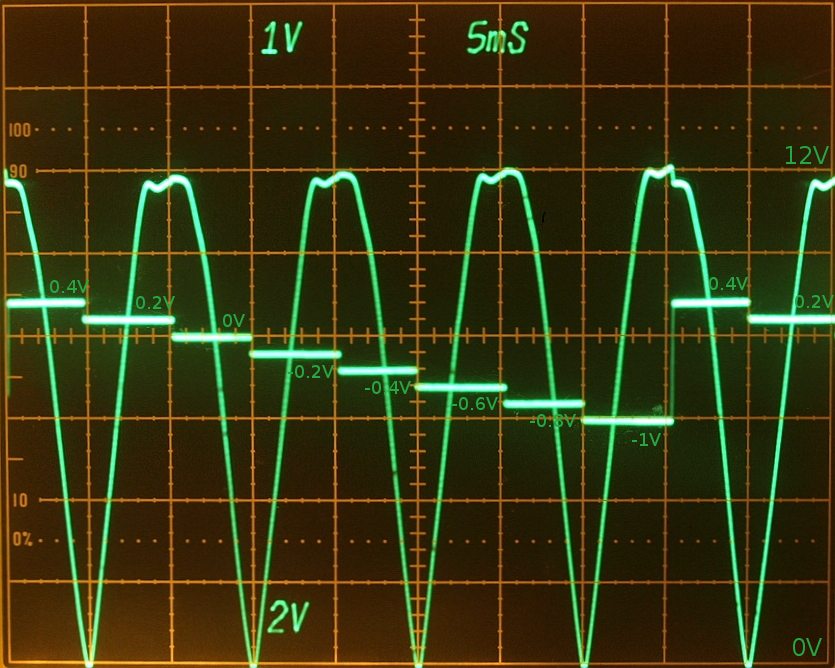

7.9DIV * 1V/DIV = 7.9V

7.3DIV * 5mA/DIV = 36.5mA

Resistance = 7.9V/36.5mA

Resistance = 216.4 Ohm

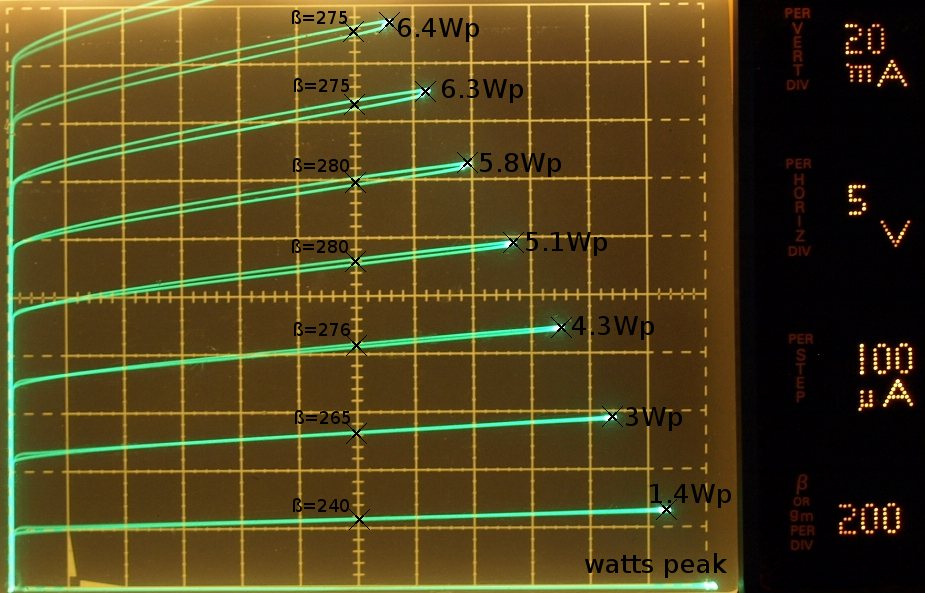

Applied Peak Power

hor.=9.7DIV and vert.=8.9DIV

hor.=9.3V and vert.=44.5mA

Peak Power = 414mW

(note: use most top/bottom and right/left

graticules for delta measurement only when

CRT geometry is in accurate condition)