|

|

|

|

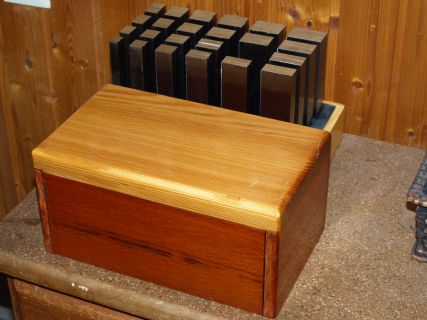

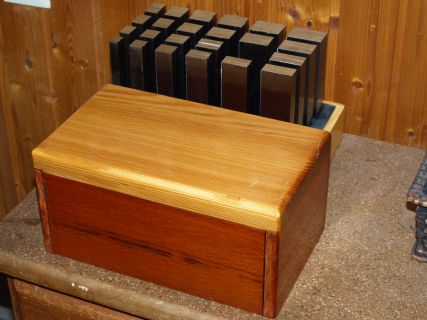

| The top cover is made of tigerwood and a needle tree. Surface polished with blond shellac. |

all wood parts are milled on the CNC machine |

parallel plates with a length of 140mm |

it is a please on the table |

| Parallel

plates are very useful, allowing a parallel position of the workpiece

in the vice. The shown set made from a quality manufacturer. Parallel

plates are must have for working with a milling machine. |

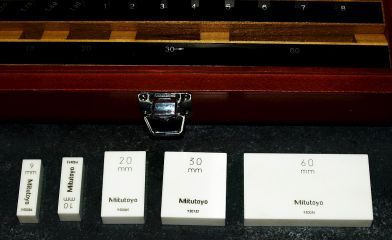

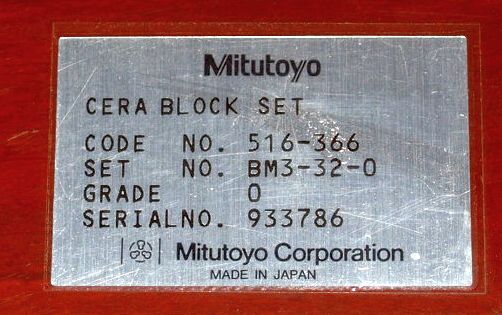

Ceramic Cera Block Set

|

|

|

|

|

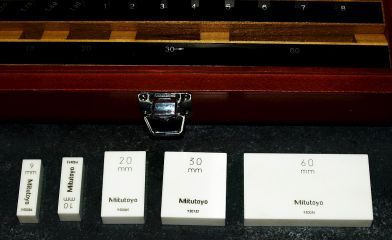

| Mitutoyo Cera Block Set Grade 0 |

such a Cera Block Set is something for life |

different size up to 60mm |

material is almost ageing free, the biggest advantage. In addition this ceramic is very hard and need no Vaseline.

Polished high quality ceramic and accurate with Grade 0. |

|

|

|

|

| a pleasure to work with them |

the largest one |

they are very hard, be careful, they can break |

|

Tungsten Gauge Block Set

|

|

|

|

|

| Tungsten Gauge Block Set in a shellac polished wooden box |

Hommel Hercules |

I put inside a pieces of leather

for cleaning the blocks and cotton gloves for touching them. The gloves

also prevent heating up the block by the warm hand. |

Tungsten Carbide is a hard

metal, heavy, high density. A steel with less ageing, but not so less

ageing as ceramic. The Tungsten Carbide has very less oxidation. |

|

|

|

|

Expansion temperature cofficient 4.23*10-6/°C at 20°C

for comparison:

Aluminium 21 to 25, Stainless steel 10 to 17, Copper 16, Brass 18, Steel 12, Titanium 9, Plastics 40-120

Tungsten should be used close to 20°C, because the material of most

common workingpieces has a higher temperatue coefficient.

|

Grade 0 is a precision grade with

high accuracy. A Tungsten Carbide Gauge Block should be useful for a

very long time. I observed Tungsten has less ageing than a steel block.

Tungsten has a quality one step behind cera-blocks, but in general more

reliable than steel blocks. Consider also Tungsten is very hard, be

careful when touching a metal working piece, can create marks, similar

material to milling tools. NormalyTungsten blocks are more expensive

than steel blocks. |

Typical grey color of Tungsten

hard metal. Very less Vaseline or Balistol is enough for a Tungsten

block. The polished and lapped side shines with intensity. |

|

Steel Gauge Block Set

|

|

|

|

|

Steel Gauge Block Set

polished with shellac |

Inside with a leather and a linen for cleaning |

Accuracy Grade 1 is a class lower compared to 0 |

Steel Gauge up to 90mm |

The steel gauge block is useful when

working on steel workpieces, both metals having a similar thermal

expansion coefficient. Therefore the ambient temperature coefficient

cancels out even when used under 15°C or 30°C, so far the TC is

similar. Steel is softer compared to Tungsten Carbid.

Steel require after use Vaseline or Ballistol, but should be removed

before use, a disadvantage compared to ceramic blocks. Use also gloves

to reject thermal expansion caused by the hand heat. I observed

this with old steel gauge set, some of the blocks are shrinked a little

bit (not much) compared to the cera block reference. Steel gauge blocks

require sometimes a calibration to check their accuracy, especially in

an unknown condition or after byuing a second hand set with unknown

history. Ageing is a topic for steel block sets, but I can`t say if

modern steel quality behave the same, ageing of steel is known since

decades, depends much on the method the steel has been manufactured. In

comparison measurents my Tungsten set is closer to cera block set than

the steel set. A safe statement can only be done after controlled

calibrating with known standards.

Many measurement errors appearing caused by the user (not cleaned,

temperature difference, not used at 20°C). Consider also the

application and in my case a hobbiest 100kg CNC milling machine,

currently used without precision collets in the spindle - the steel

ageing is absolutely not a problem in the accuracy range of my metal

equipment. Anyway with the ceramics a fine reference at home. These old

unknown condition steel is fine for using in "rough applications with

less accuracy" where to prevent the ceramics from a damage. It is the

same when choosing at home between 20 oscilloscopes, you always choose

the one suitable for the task. |

Optical flat glass

|

|

|

|

|

| Optical flat glass from CCCP |

this planglass has a large diameter 120mm, not often seen |

I wished I could read this language |

|

|

|

|

|

| another type from Japan |

small size |

|

|

| With a optical flat you can test a

polished. lapped metal surface if it is very flat. This test require a

light source with one wavelenght and the glass. Optical flat used

for producing fringes from a monochromatic lightsource, e.g. a laser

light, sodium light, but also works with sunlight or daylight floescent

lamps.

With a monochromatic wavelenght light source it more easy to see the

fringes. The web is full of information how this technology works. |

Lapping plate

|

|

|

|

|

lapping plate made on a precision lathe machine

used for lapping a flat metal surface |

|

|

|