After some years of not

using the Plug-In, the 7S14 didn't work and I was very sad. What to

do?, first I thought the instrument is broken and printed out the

manual. Later I found that there are four small batteries inside, I

also read it in the TekScope yahoo forum. There are small 1.35 volts

mercury cells inside.

Something about batteries:

These type of batteries were often used as reference voltages in many

test equipment devices. For example also the Fluke

540B AC Standard

use this type of batteries as reference voltage or the

419A

DC Null Voltmeter. The batteries were often used in a ratio

measurement, this means it doesn't matter if the battery shows 1.2 volt

oder 1.45 volts. The only "must" the battery have to be stable during

the measurement itself.

The mercury cells having a long live time, less self discharge and good

power. Another very good thing is their discharge curve vs. lifetime

keeps very stable over a long period, this is very good for using as

reference. Mercury were used many times as reference voltage in older

photometers.

The only strong disadvantage is, they were no more selled in Europe, I

guess also in no more selled in the USA, this leds to the fact - no

more a high volume production of these cells anymore.

Which alternatives? Easiest is a 1.5V alkaline watch battery,

I choosed this type, because already in the house available, their

disadvantages are: less capacity, I guess a higher self discharge

curent (I don't know) and a much more worser discharge curve vs.

lifetime! the last is the worst disadvantage. But in the case of the

7S14 I didn't care. Other useful batteries are Wein cells oder Air-Zinc

batteries, which have a high power but their self discharge starts much

after activating.

Best alternative for a mercury cell would be Lithium battery with about

1,5 to 1,65 volts. These batteries having a very low self discharge vs.

storage time, even 15-20 years should not be a problem. They have a

wonderful high power and capacity and I guess also an excellent usefull

stable voltage over a long time. Some big famous companies manufactores

these Litium cells in the AAA-size micro package. Unfortunately an AAA

size is toooooo big, no space within the shielded area for the

batteries. This forced me using a standard watch battery.

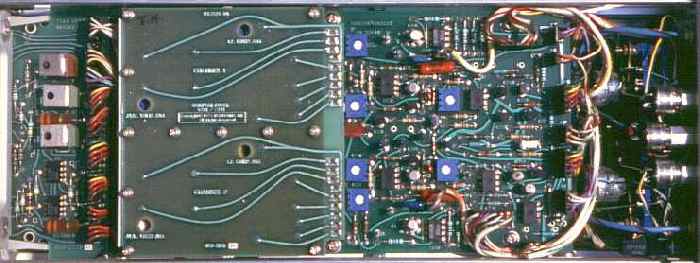

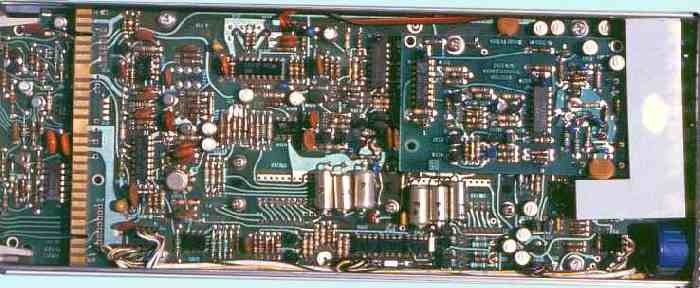

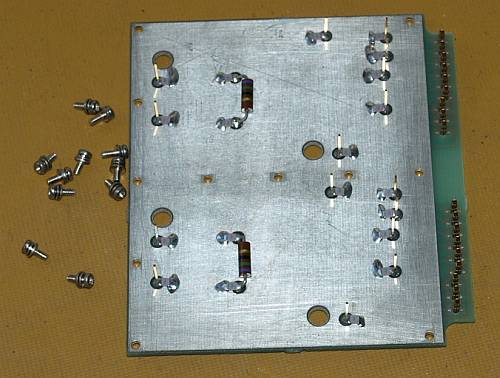

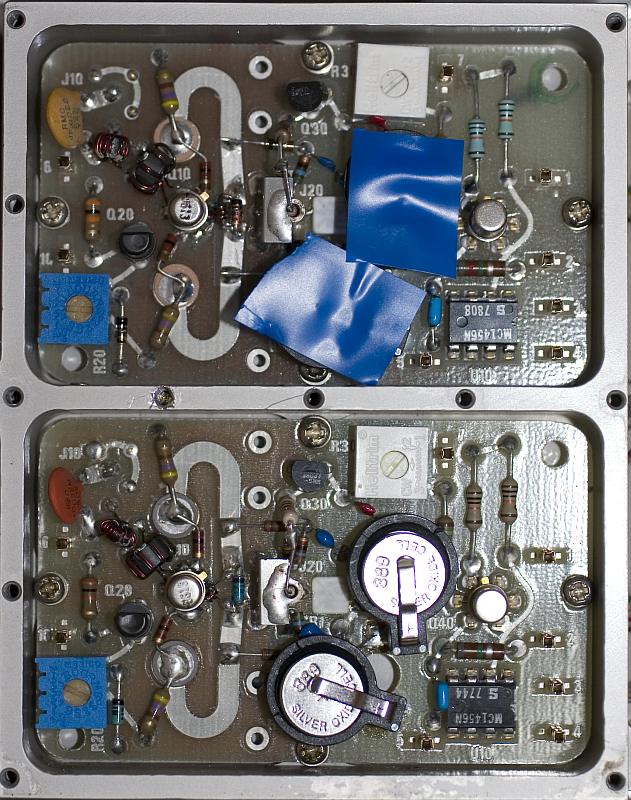

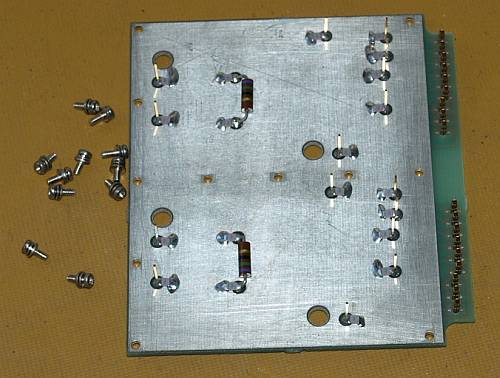

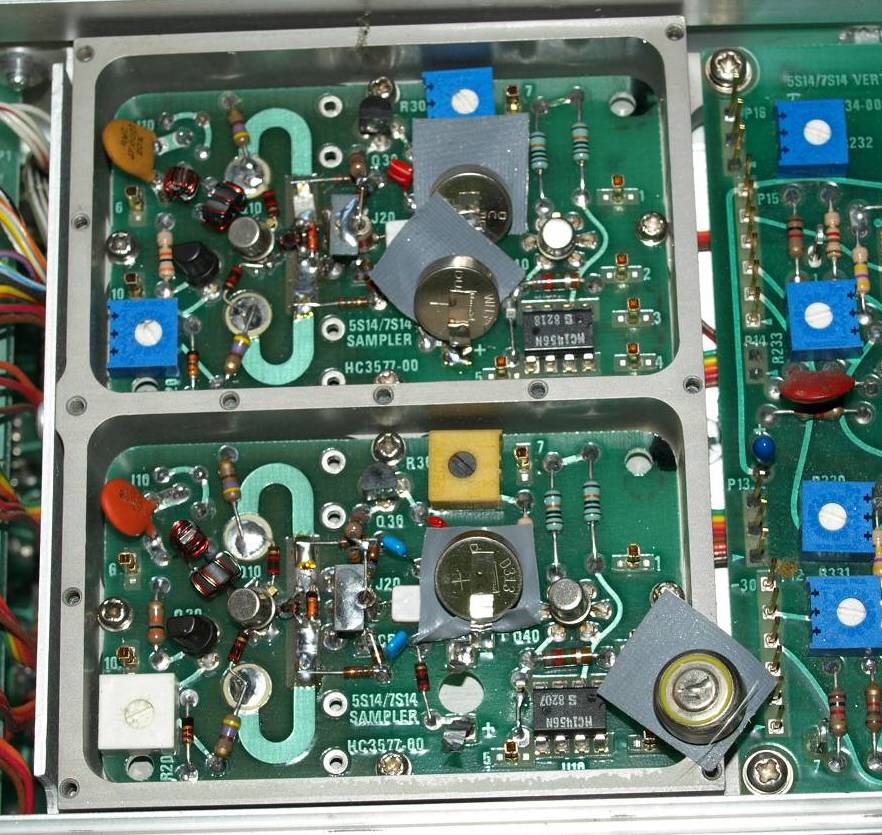

Remove this PCB reaching the batteries.

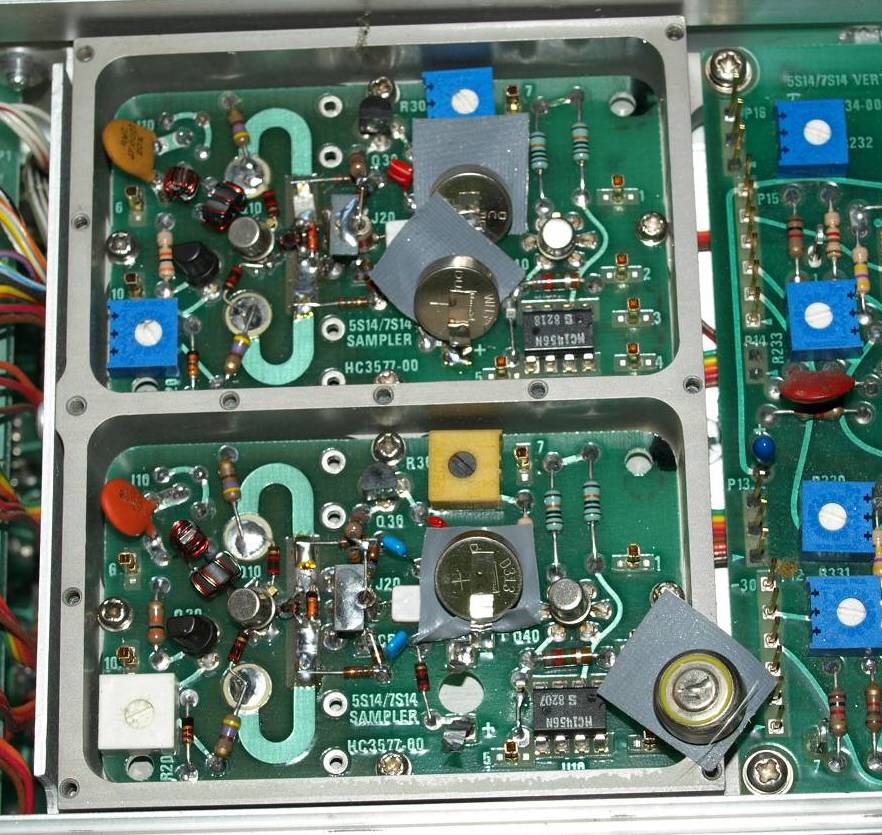

Photo shows the location of the four batteries, they were welded with

small stripes of metal and soldered on the PCB. The grey foil isolates

from a short-circuit.

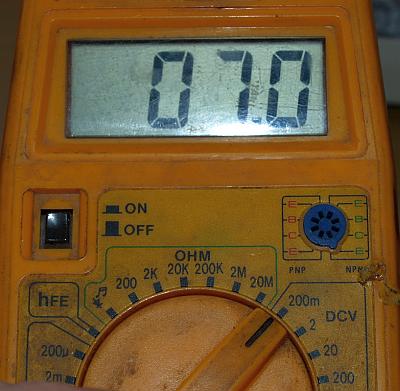

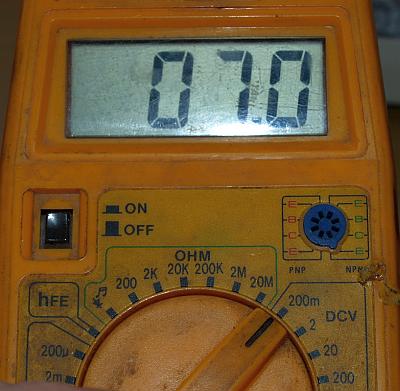

These are the empty original batteries. Only 7mV remain - these are really the nice faults and easy to find.

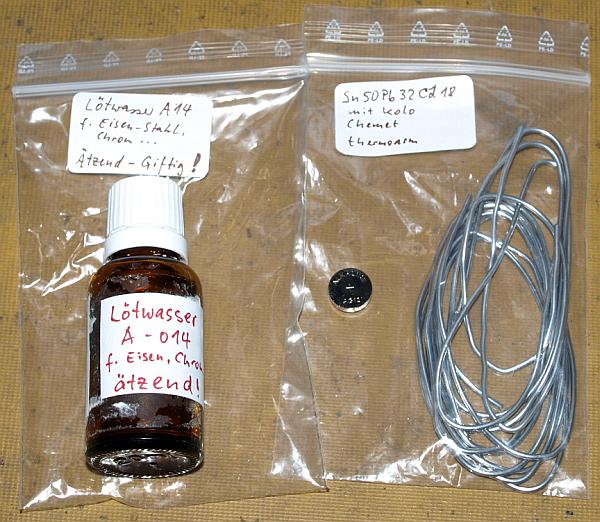

The new ones 1.5 volts. They came from a cheap warehouse, many of them for one Euro, I will see how long they are alive.

How to solder these batteries?

BOTH ARE SERIOUS TOXICALLY !!!

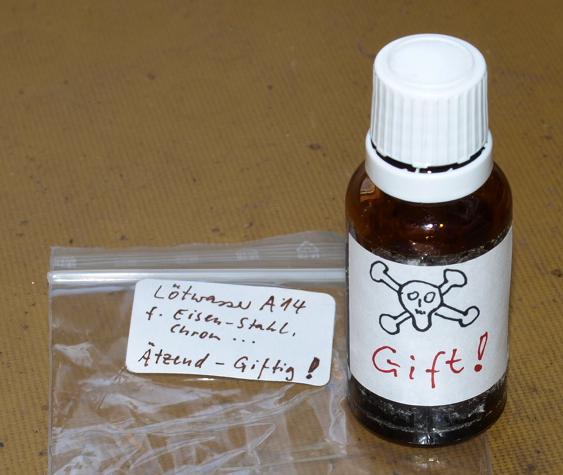

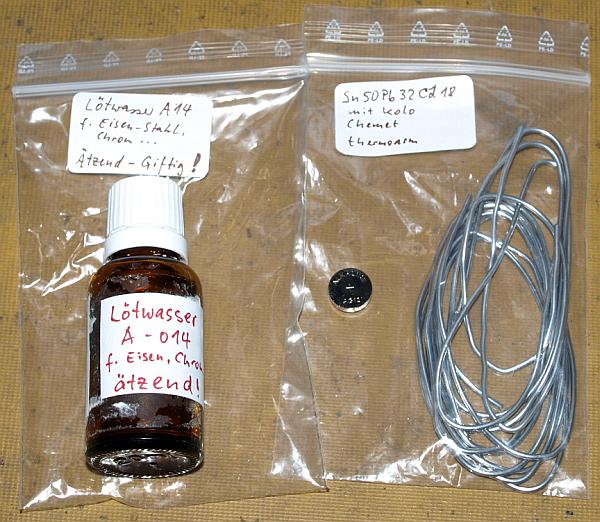

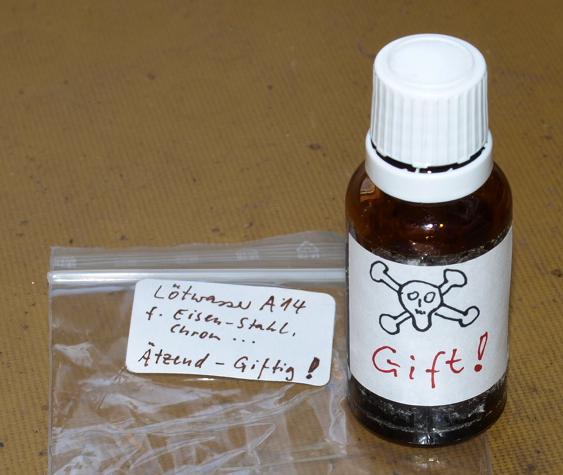

A nice friend knowing via Internet made one day such a gift.

Left - a strong flux-material which

can solder many metalls. Right - special solder wire with Sn

50%. Pb 32% and 18% Cadmium. This solder has a very low melting

point of approximately 145°C. This low melting point allows the use

of less solder-iron temperature and less heat transfered into the

batterie. Much heat should be avoided, it can destroy the gasket of the

battery very fast and I also don't what happens inside the batterie if

using excessive heat. This solder will be used normally for high

precision DC metrology instruments (me too) or inductive soldering

machines, if heat should be minimized. If you don't like Cd

solder-wires, nowadays there are many solder-wires available with low

melting points, many without the very poisonous Cd. Other low melting

point examples containing Indium or Bismuth. Try a web search for

"Indium", you will find a company close to that name with huge

unbelievable number of solder wires types. About the sample

prices you will start thinking. I used the one I had in the house just

at the moment. Using standard Sn Pb Cu solder wire it's getting

risky for the batteries. May be soldering at all will destroy the

batteries, I don't know - but I also don't care - it works or it don't

works and if they are empty next week - bad luck.

Use always protection eye classes for soldering a batterie, if the

gasket explode caused by the heat, you never know which kind of acidly

materials coming out of the batterie?, may be direct in your eyes.

Don't trink that flux, wash your fingers after work, don't eat

your lunch during soldering, be carefull with the Cd solder wire and

don't sit in the smoke during soldering!!!, blow the smoke away by a

fan or do it outside.

In my house I can solder with

whatever I want. Before soldering the batteries the surface should be

scratched with a sharp metal tool or a sandpaper, it increase the

micro-surface for a better solder junction. Unfortunately the original

batteries are no more available, this force such solutions saving

the life of a worthwhile 7S14 Plug-In.

For soldering I recommend a big solder iron, transfering within a short

time a lot of heat to the solderpoint, don't solder longer than

necessary!

After replacing, measure the distance between anode of the batterie

and ground signal of the PCB on top, preventing a short-circuit.

Isolate the batterie with a tape against the top PCB.

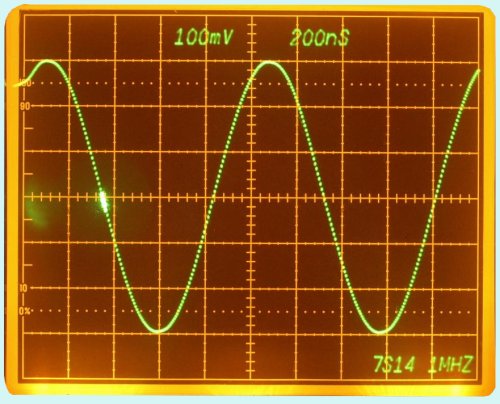

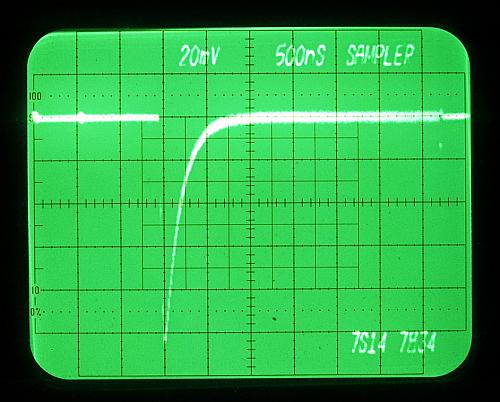

Instrument works again

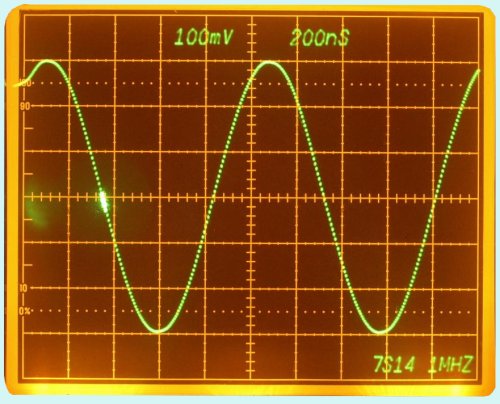

300mV 1MHz sine wave singal, yeah it works again, displayed on a

7904. Dots appearing because "Hold" button is activated.

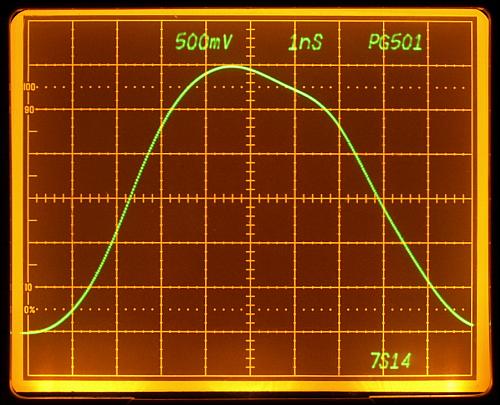

Taken from

PG501 Pulsgenerator

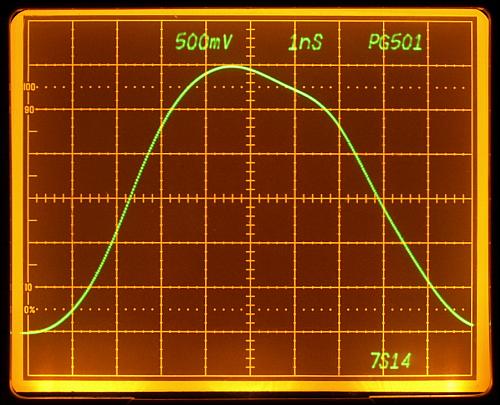

This signal is measured on a

7834 fast storage oscilloscope together with the 7S14.

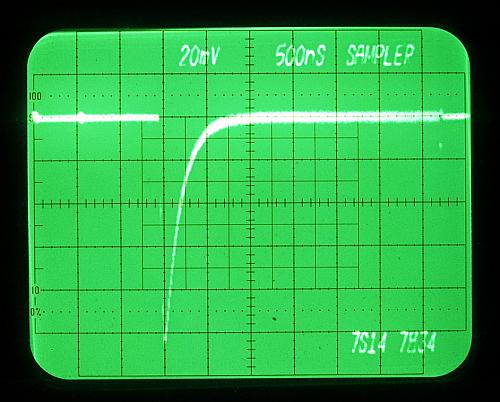

A storage oscilloscope is a nice

mainframe for a sampling Plug-In. With the variable

persistance, low repetition and lower frequency signals getting

easy observable. For higher frequencies shows any 7000 series mainframe

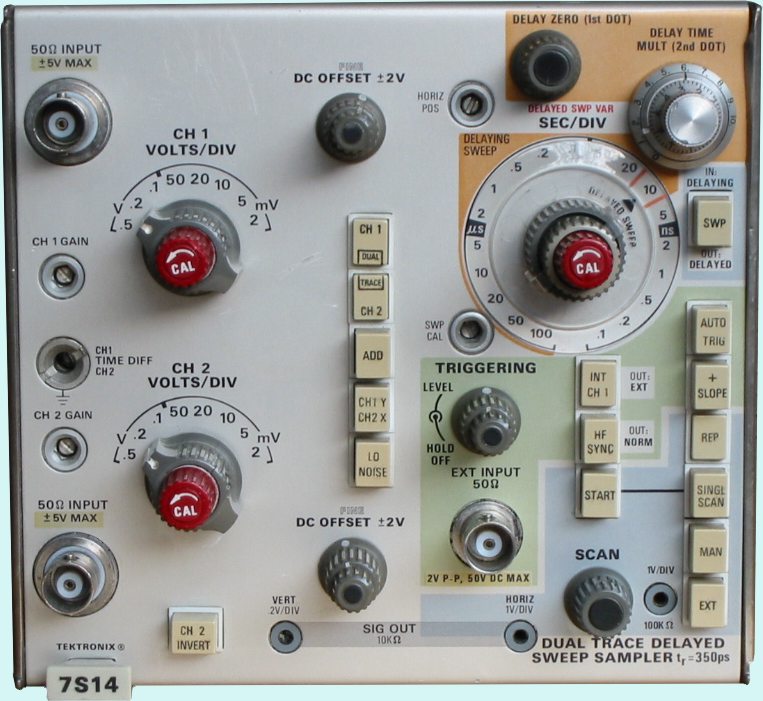

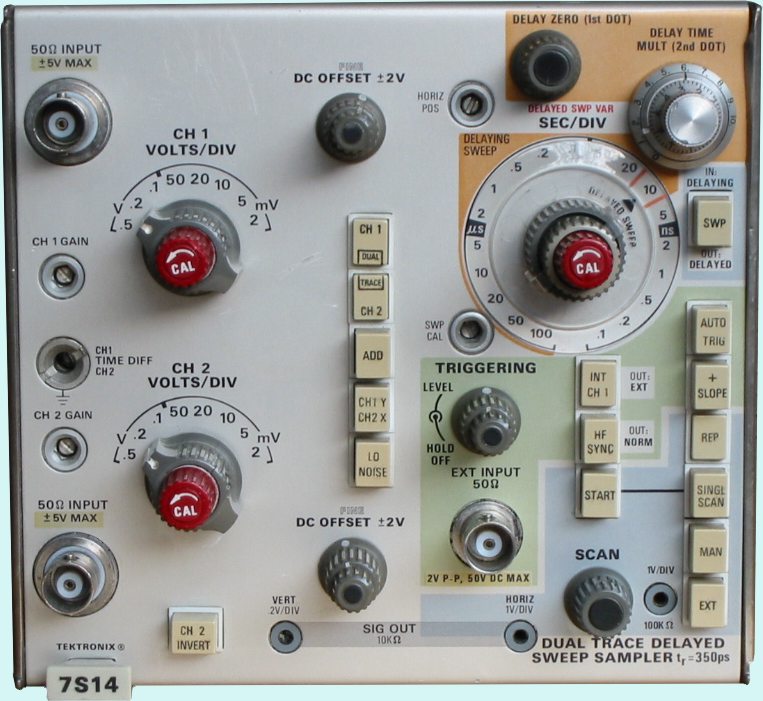

good results. The Plug-In use one vertical and one horizontal slot.